Coupe to Convertible Instructions

STEP 1: -REMOVE SEATBELT BOLTS “SHOWN”

-REMOVE SCREWS FOR INNER ROLLBAR

-REMOVE INNER PLASTIC ROLLBAR

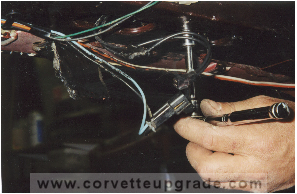

STEP 2: CUT WIRE BUNDLE “SHOWN”

– DISCONNECT GOUND WIRES FROM ROLLBAR

STEP 3: REMOVE ALL NUTS HOLDING HATCH AND 3RD BRAKE LIGHT IN PLACE

STEP 4: DISCONNECT AND REMOVE ALL STRUTS

STEP 5: WITH ANOTHER PERSONS HELP CAREFULLY LIFT REAR WINDOW FROM CAR

STEP 6: REMOVE ALL THREE PLASTIC PIECES FROM REAR CARGO AREA

STEP 7: REMOVE WEATHERSTRIP FROM CAR

STEP 8: CLEAN GLUE OFF EDGE AROUND CARGO AREA USING SOLVENT

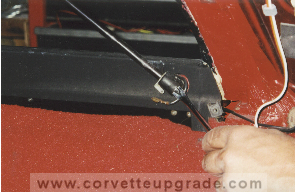

STEP 8: UNCLIP WEATHERSTRIP FROM DOOR JAMB AND SECURE IT UP WITH TAPE. “SEE NEXT PICTURE”

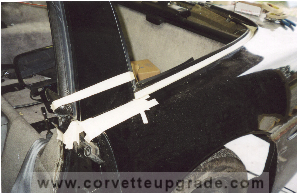

STEP 10: MARK ALL AREAS SHOWN WITH TAPE IN PICTURE

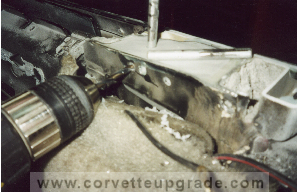

STEP 11: CUT AREA AROUND CARGO AREA WITH SAWSALL

STEP 12: CUT ROLLBAR OFF ON EACH SIDE. NOTICE HOW THE ANGLE OF THE SAW BLADE IS LEVEL WITH THE CAR. CUT RIGHT DOWN THE SEAM LINE OF WHERE THE ROLLBAR MEETS THE QUARTER PANEL. MAKE SURE YOU DO NOT LET THE BACK EDGE OF THE SAW BLADE DRIFT AS YOU MAKE THE CUT.

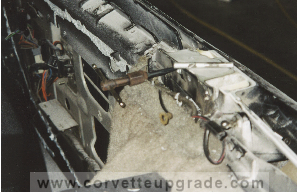

STEP 13: GRIND ALL AREAS WHERE YOU CUT. MAKE SURE THAT YOU GRIND AREA SHOWN IN PICTURE ALMOST FLAT WITH QUARTER PANEL.

AT THE SAME TIME GRIND AREAS OF EPOXY INSERTS WERE GLUE BONDS “SEE NEXT PICTURE FOR AREAS”

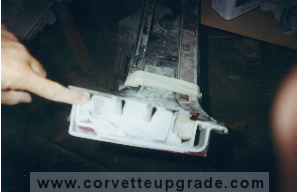

STEP 14: MIX 1 1/2 TUBES OF EPOXY ADHESIVE AND APPLY TO LOWER INSERTS AS SHOWN

STEP 15: POSITION LOWER INSERT IN HOLE , DRILL, AND SECURE WITH SMALL SCREW. USE LEFTOVER MIXED EPOXY TO FILL VOIDS AROUND INSERT. MAKE SURE TOP OF PAD IS LEVEL WITH CAR

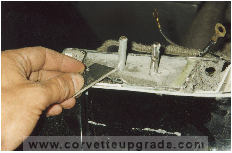

STEP 16: POSITION PINS IN HOLES AND MARK. grind TOP HALF OF PIN. NOTICE NOTCHES GROUND IN PIN ON LEFT SO THAT EPOXY HAS BETTER ADHESION.

STEP 17: DRILL HOLES FOR SET SCREWS “ALAN SCREWS” 1/2″ BELOW LEVEL. PUT PINS IN HOLES REDRILLTO MARK PINS AND GRIND A V ONTO PIN SO SET SCREWS WILL LOCK.

STEP 18: TAP HOLES WITH INCLUDED TAP.

“NOTICE V GROUND INTO PIN”

STEP 19: PLACE 2″TAPE OVER INSERT AREA AND QUATOR PANEL.

PUSH PINS THROUGH TAPE

LOCK ALAN HEAD SET SCREWS IN PLACE WITH ALAN WRENCH

MIX 1 1/2 TUBES EPOXY AND APPLY ON UPPER INSERTS. MAKE SURE YOU PUT ALOT OF EPOXY INTO THE HOLES WHERE THE PINS GO.

CAREFULLY SET INSERTS INTO POSITION OVER PINS.

STEP 20: WITH ANOTHER PERSONS HELP PLACE ROLLBAR INTO POSITION OVER THE TOP OF GLUED INSERTS. PUSH DOWN UNTIL BOTTOM EDGE IS ALMOST FLSH WITH QUATOR PANELS. SECURE T-TOP ROOF INTO POSITION FOR ALLIGNMENT WAIT 1 HOUR FOR EPOXY TO HARDNEN BEFORE LOOSING SET SCREWS AND REMOVING ROLLBAR.

STEP 21: ROLL OVER ROLLBAR AND FILL VOID AREAS AROUND INSRTS WITH 1/2 TUBE EPOXY. LET SET AND FILE OR GRIND AREA SMOOTH.

STEP 22: NOTCH BLACK PLASTIC AREA SHOW FOR SEAT BELT CLEARENCE.

STEP 23: DRILL AND ATTACH SEAT BELT HARNESS AS SHOWN

STEP 24: CUT INNER ROLLBAR WITH USING INCLUDED TEMPLETE

STEP 25: ATTACH REAR GLASS BACK TO ROLLBAR “SEE STEP 3”

STEP 26: INSTALL INNER ROLLBAR COVER BACK IN PLACE

STEP 27: PLACE HINGE PIECES IN HOLES LIKE SHOWN

NOTICH HOW THE ARE MARKED DRIVER AND PASSANGER.

PLACE TAPE BETWEEN HINGE HALFS AS SHOWN

MIX 1 TUBE OF EPOXY AND PLACE ON HINGE AS SHOWN

STEP 28: POSITION HATCH IN PLACE AND PLACE SOME SORT OF WEIGHT ON HATCH AS SHOWN.

STEP 29: PAINT HATCH TO AMTCH VECHILE. AS AN OPTION YOU CAN PAINT THE PAD AREA WHEN YOU REMOVE THE ROLLBAR.

CONVERSION SHEET

STEP 1: LOOSEN 4 ALAN BOLTS “2 EACH SIDE” AS SHOWN

STEP 2: REMOVE T-TOP ROOF

STEP 3: WITH ANOTHER PERSONS HELP LIFT GLASS AND ROLLBAR FROM CAR

STEP 4: WITH ANOTHER PERSONS HELP LIFT HATCH INTO POSITION

STEP 5: TIGHTEN ALAN HEAD BOLTS AS SHOWN

STEP 6: PUSH HATCH DOWN UNTIL LATCH CATCHES